|

|

Electric Hot Water Spray Steam Retort High Pressure Industrial Autoclave Sterilization Pot

Collect

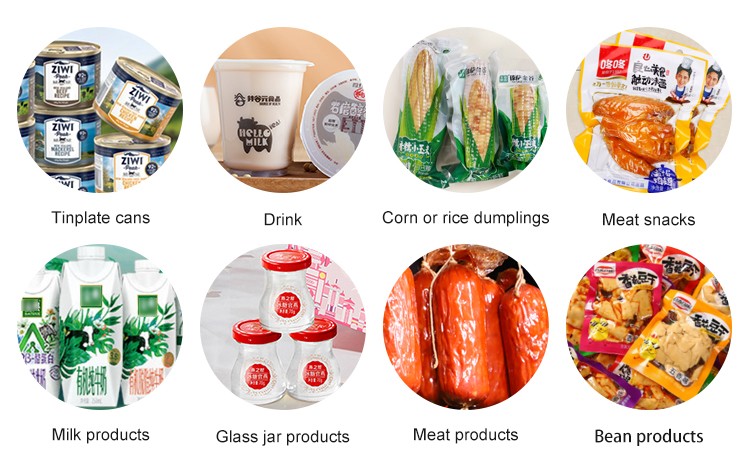

Electric heating spray sterilization pot is a device that uses electric heating medium (such as water or steam) and spray method to sterilize food. Its core features include: Working principle By using an electric heating system to heat water or steam to a predetermined temperature, the mist like hot water is evenly sprayed onto the surface of the food by a spray device, achieving a rapid and comprehensive sterilization effect. The rapid heating and cooling process is particularly suitable for sterilization treatment of soft packaged foods. main features Uniform temperature: Spray mist like hot water through top or side nozzles to ensure uniform surface temperature of the product and no dead corners for sterilization; Fast and efficient: using efficient heat exchangers for rapid heating and cooling, shortening the sterilization cycle; Wide applicability: Suitable for products made of different materials such as glass bottles, tin cans, plastic bottles, and flexible packaging. classification According to the heating method, it can be divided into: Pure electric heating type: directly using electric heating elements to heat process water or steam; Electric heating+steam assisted type: combining electric heating and steam cycle system to improve efficiency

Application

Product Features 1.Very stable temperature in the pot A. The continually showering water comes from the nozzles vertically located at the 4 corners of every tray so that the termerature in the pot maintains very phase of the sterilization process. B. As the temperature in the pot is very stable FO value variation & over cooling could be minimized. 2.Direct heating, indirect cooling, no secondary pollution The atomized recycle water is heated directly through steam diffusion pipe, so the temperature rise rapidly. Normally the water temperature in the pot only takes 12 minutes to rise from 20 °C to 121 (°C under 0.5 MPA steam pressure. Cooling down is made by continually recycling the water through the pipe transformer. 3.Temperature rise &drop step by step The temperature could rise and drop in ten phase with computer control. Gentle linearity temperature rise and drop protect the fragile food and glass bottles. The makes complete sterilization and maximum preservation of food taste and colour. Also contribute to the consistency of sterilization effect on the whole batch of product. 4.Soft water sterilization , beautiful clean package surface Coolant water does not enter in the pot and not contact with package, which reduce the surface pollution and save cost. 5.No special requirement on the water coolant It could be city water, underground water or sea water, which saves water source and reduces the cost. 6.Perfect pressure control&suitable for gas pack 7.Control system Siemens touch screen(or mitsubishi touch screen) Non-paper recorder(paper recorder) Imported automatic valve 8.Measure F Value, Display F Value, Control F Value parameter We will design sterilization equipment based on your product, and we welcome you to leave us a message for discussion

|